09/29/2024

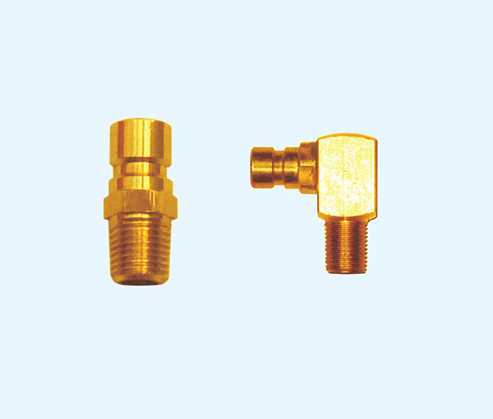

In addition to requiring sufficient strength and toughness during operation, the surface properties of high-precision mold components are crucial for their working performance and service life. The imp…

09/29/2024

With the continuous development of the economy and the improvement of people's living standards, the demand for spiritual and material culture is becoming higher and higher. This demand has also driven…

09/29/2024

On the road to becoming a true strong country in the field of mold and metal stamping parts, China still needs to make various improvements, which involve various aspects of the current development of …

09/29/2024

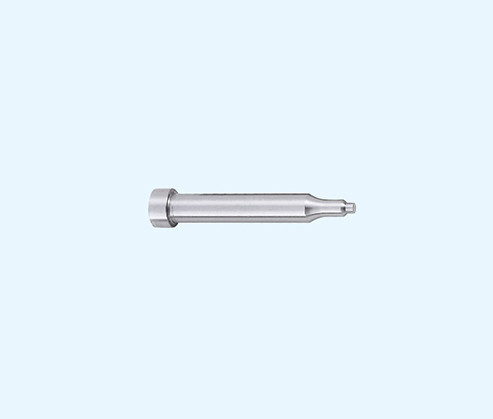

As is well known, the top pin is very prone to rusting. If the plastic mold parts factory finds that the top pin is rusted and does not handle it, its service life will be quickly consumed and become l…

09/29/2024

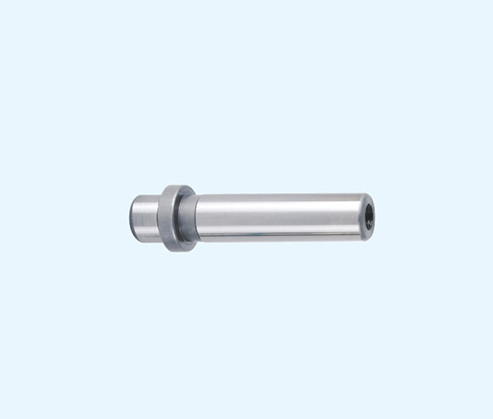

Grinding is a common process for hardware mold accessories after long-term use. The abrasive particles embedded on the grinding tool will perform precision machining on the surface of the workpiece dur…

09/29/2024

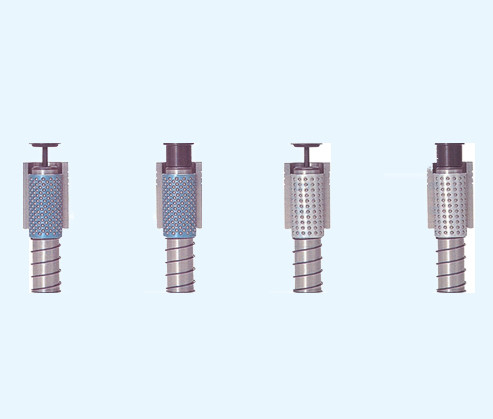

Rear mold needle is a common plastic mold accessory in the market nowadays, and the service life of high-quality rear mold needle is different from that of ordinary quality rear mold needle. So when ch…